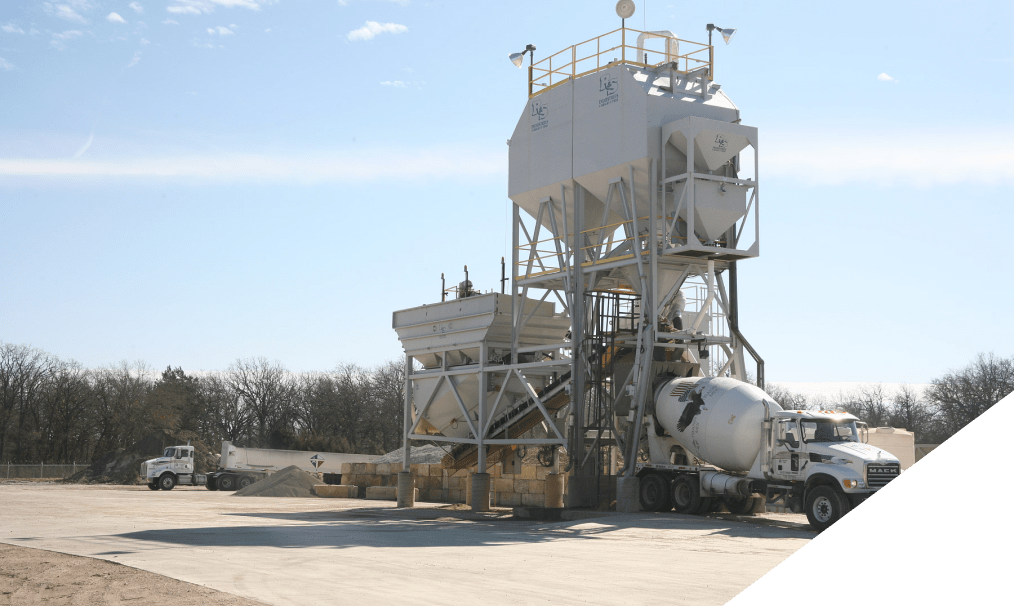

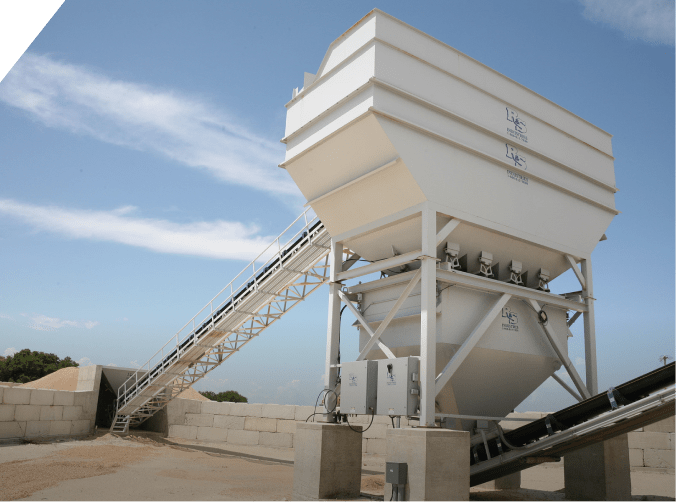

R&S stationary batch plants are designed for unmatched reliability, longevity, and performance. Engineered to meet the most demanding requirements, our plants offer robust storage solutions and are capable of handling the production needs of both large and small-scale projects. Whether your needs involve smaller production volumes or large-scale, highly efficient operations, we provide customized solutions tailored to your unique site layout and operational needs.

With R&S, you can count on your batching plant to deliver consistent, high-quality performance over the long term. From initial design to final execution, we ensure your project is completed with efficiency and effectiveness.

The Apache Series blends robust construction with innovative features, delivering a reliable, high-performing plant suited for a variety of batching and production needs. Designed for environments with space constraints, the Apache Series offers a smaller footprint, flexible configurations, and long-term durability. It’s the perfect solution for producers seeking both efficiency and reliability in their operations, whether for startup ventures or expanding businesses.

24″ to 36″ wide, capable of running up to 350 FPM.

Fast material transfer with adjustable speeds to accommodate various production needs.

10 to 25 HP

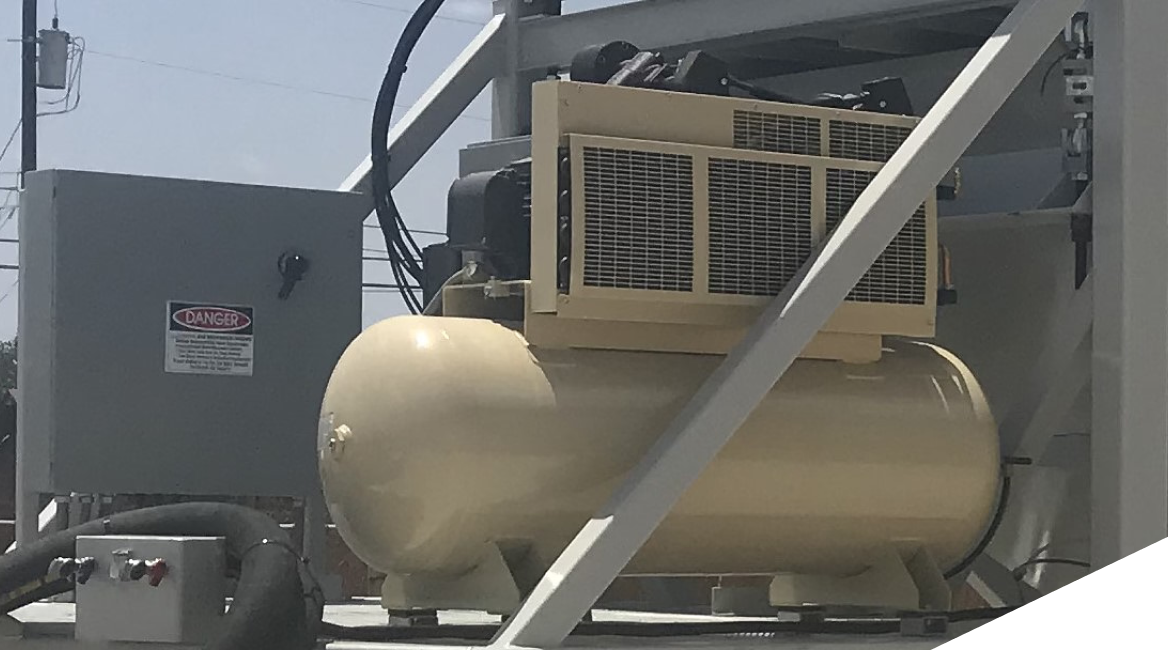

Includes pressure regulator, lubricators, and moisture trap for consistent air pressure and smooth operation.

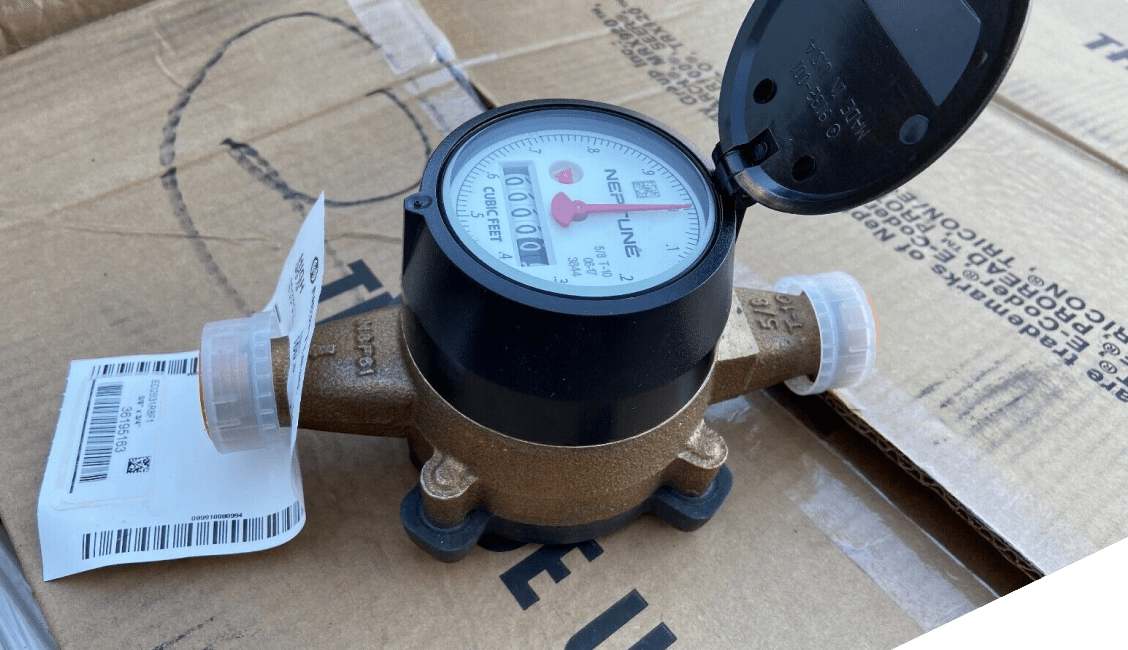

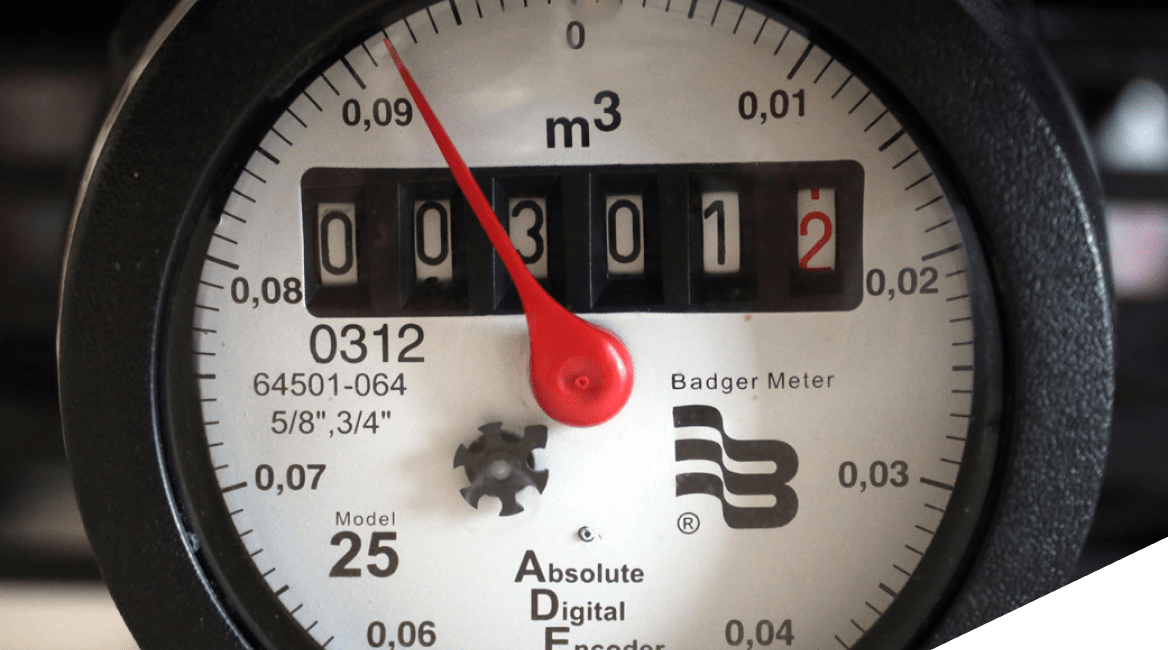

Includes standpipe and inlet strainer.

Includes standpipe and inlet strainer.

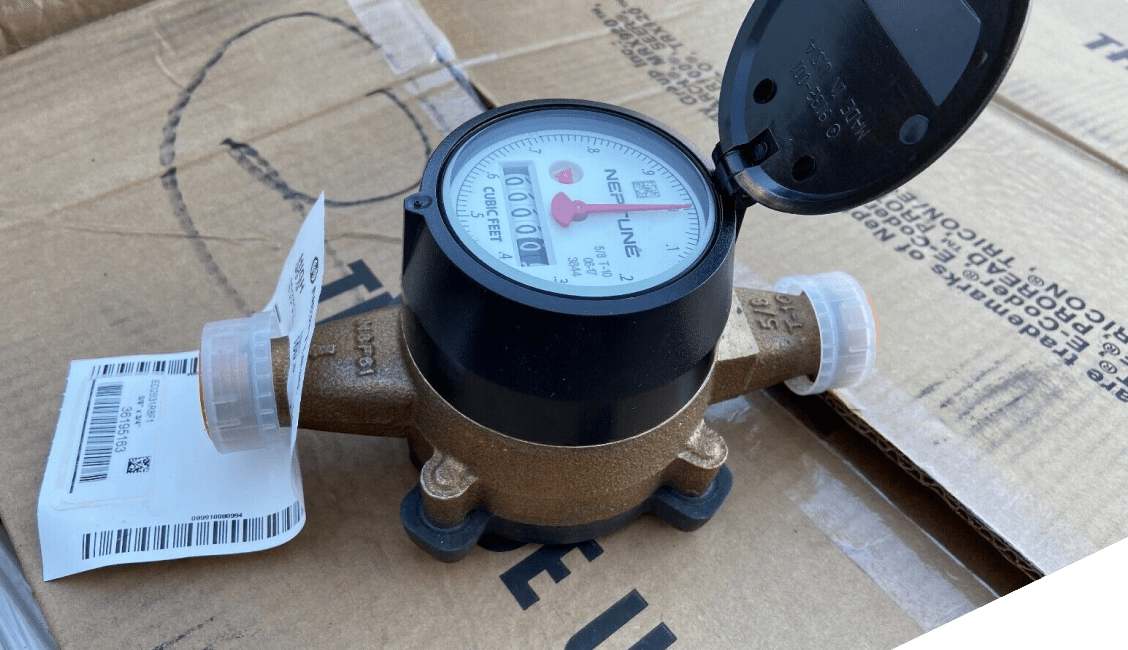

500-gallon surge tank constructed of 3/16” plate with 3” inlet system complete with butterfly valve, actuator, and solenoid with air mufflers for a more controlled close rate for precise water measurement.

Features manual emergency slide gate, spring-loaded pressure relief valve, and optional two-compartment silo with a double steel wall, channel bracing, and weep holes for enhanced flow control.

Externally removable aeration pads provide optimum cement flow and easy maintenance.

8” butterfly gates on the cement silo and batcher are adjustable for precise batching control.

Includes a Pulse-Jet Silo Top or Free-Standing Dust Collection System with an Auto-Dust Reclaim System to reduce environmental impact and improve efficiency.

Features 1/4” sloping sides and 3/16” vertical sides in the aggregate bin and batcher for added durability in high-demand environments.

Constructed with wide-flange beams for strength and longevity.

Includes vulcanized rubber-lagged head pulley, self-cleaning tail pulley, and heavy-duty steel plate in high-wear areas to prevent premature wear and ensure long-term durability.

Double clam gear segmented gates with 1” thick gear quadrants and 1” x 3/4” stiffener bars for smooth, efficient discharge.

Dual double-clam discharge gates with air vibrators help prevent clumping and ensure smooth material flow.

Designed for minimal maintenance and long-lasting performance.

Equipped with main disconnect, fuses, heaters, motor starters, and a 110V transformer for safe and efficient power distribution.

Available in manual or computerized versions with NEMA-rated enclosures for durability and ease of use.

Designed for 460V/3PH/60HZ power input, with other voltage options available for international use.

Each plant is fully assembled and tested at the factory before shipping, ensuring it’s ready for fast setup and operation upon delivery.

The plant directs material flow in a vertical column directly above the gate opening, reducing wear and increasing batching speed.

Rebuildable air cylinders and high-quality center-line valves provide ease of maintenance and reliable performance.

Built to withstand potential impacts from wheel loaders or mixer trucks, ensuring minimal damage.

All production rates are theoretical, designed for maximum efficiency and output.

The Apache Series blends robust construction with innovative features, delivering a reliable, high-performing plant suited for a variety of batching and production needs. Designed for environments with space constraints, the Apache Series offers a smaller footprint, flexible configurations, and long-term durability. It’s the perfect solution for producers seeking both efficiency and reliability in their operations, whether for startup ventures or expanding businesses.

The Comanche Series combines high-performance capabilities with durability and flexibility, making it ideal for a variety of production environments. Designed for efficiency and ease of operation, this plant meets the demands of both startup producers and established businesses expanding into new regions. Below are the key features that set the Comanche Series apart:

24″ to 36″ wide, capable of running up to 350 FPM

Fast material transfer with adjustable speeds to accommodate various production needs.

10 to 25 HP

Includes pressure regulator, lubricators, and moisture trap for consistent air pressure and smooth operation.

with standpipe and inlet strainer.

with standpipe and inlet strainer.

500-gallon surge tank constructed of 3/16” plate with 3” inlet system complete with butterfly valve, actuator, and solenoid with air mufflers for a more controlled close rate for precise water measurement.

Features manual emergency slide gate, spring-loaded pressure relief valve, and optional two-compartment silo with a double steel wall, channel bracing, and weep holes for enhanced flow control.

Externally removable aeration pads provide optimum cement flow and easy maintenance.

8” butterfly gates on the cement silo and batcher are adjustable for precise batching control.

Includes a Pulse-Jet Silo Top or Free-Standing Dust Collection System with an Auto-Dust Reclaim System to reduce environmental impact and improve efficiency.

Features 1/4” sloping sides and 3/16” vertical sides in the aggregate bin and batcher for added durability in high-demand environments.

Constructed with wide-flange beams for strength and longevity.

Includes vulcanized rubber-lagged head pulley, self-cleaning tail pulley, and heavy-duty steel plate in high-wear areas to prevent premature wear and ensure long-term durability.

Double clam gear segmented gates with 1” thick gear quadrants and 1” x 3/4” stiffener bars for smooth, efficient discharge.

Dual double-clam discharge gates with air vibrators help prevent clumping and ensure smooth material flow.

Designed for minimal maintenance and long-lasting performance.

Equipped with main disconnect, fuses, heaters, motor starters, and a 110V transformer for safe and efficient power distribution.

Available in manual or computerized versions with NEMA-rated enclosures for durability and ease of use.

Designed for 460V/3PH/60HZ power input, with other voltage options available for international use.

Each plant is fully assembled and tested at the factory before shipping, ensuring it’s ready for fast setup and operation upon delivery.

The plant directs material flow in a vertical column directly above the gate opening, reducing wear and increasing batching speed.

Rebuildable air cylinders and high-quality center-line valves provide ease of maintenance and reliable performance.

Built to withstand potential impacts from wheel loaders or mixer trucks, ensuring minimal damage.

All production rates are theoretical, designed for maximum efficiency and output.

The Comanche Series combines robust construction with cutting-edge features to provide a reliable, high-performing plant capable of handling a wide range of batching and production needs.

Designed for easy transport, flexible configurations, and long-term durability, the Comanche Series is the ideal solution for producers seeking efficiency and reliability in their operations.