The R&S Arrowhead Silo series features durable silos designed for efficient storage, easy maintenance, and long-lasting performance. We offer a range of silos, auxiliary silos, and vertical pigs in various sizes to meet the specific needs of your plant. Each silo and vertical pig is equipped with a square roof, increasing available square footage by 22%, along with safety handrails, toe boards, and a caged safety ladder for added security. Our silo systems and batches are engineered to streamline your workflow, minimize downtime, and deliver exceptional results.

R&S Industries provides a broad selection of storage options. We customize our heavy-duty silos for each plant, and offer a range of options to best fit your needs. We offer 493–1160 BBL silos and split silos with pressure tested dual walls. We can design lower support structures to fit into even the most compact sites. We also offer vertical pig silos to increase storage capacity.

The Arrowhead Silo series offers robust silos designed for efficient storage, easy maintenance, and long-term durability. Below are the key features and options for the Arrowhead Silo and its various configurations, including available upgrades.

For different storage needs, the Arrowhead Silo series offers several models, all built with the same high-quality features: as the 493 model

Capacity: 493 BBL (1972 cubic feet, 73 tons)

Capacity: 600 BBL (2400 cubic feet, 88.8 tons)

Capacity: 720 BBL (2880 cubic feet, 106.6 tons)

⦁ Capacity: 943 BBL (3772 cubic feet, 139.6 tons)

Capacity: 1012 BBL (4050 cubic feet, 149.9 tons)

Capacity: 1160 BBL (4640 cubic feet, 171.7 tons)

For additional functionality and flexibility, the Arrowhead Silo series offers a split silo with double wall partition. These upgrades provide enhanced separation and material handling capabilities, with additional components for each compartment.

Allows for dividing a single silo into multiple compartments, giving you the ability to store different materials or handle varying quantities within the same silo.

Available for all silo capacities, from 493 BBL to 1160 BBL.

Features a threaded nipple at the button of the silo that can be used to pressure test the double wall partition integrity and shows if a leak is ever resent in the future.

Includes additional components such as pressure relief valves, inspection manholes, fill lines, butterfly discharge valves with actuators and solenoids, and emergency slide gates for each compartment.

Provides the flexibility of segregating materials while ensuring efficient discharge and aeration.

The following upgrades improve silo fill performance and safety:

5” Fill Line: Replace the standard 4” line for enhanced material flow.

Additional Fill Lines: Add extra fill lines for increased capacity or to support multiple compartments.

Prevents overfilling with systems that include alarms, pinch valves, and slave valves for multiple fill lines. Available in both 4” and 5” configurations.

Ensures pinch valves can close without relying on the main air supply, useful during after-hours operation.

Monitors pressure levels and activates pinch valves to prevent overfilling when preset levels are reached.

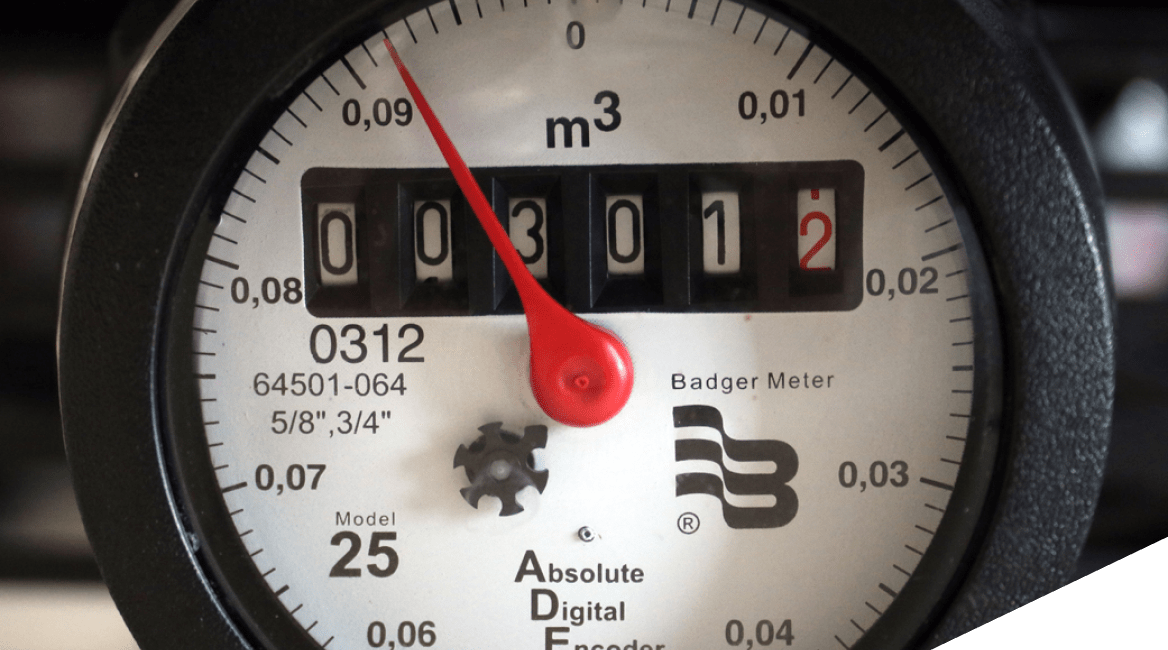

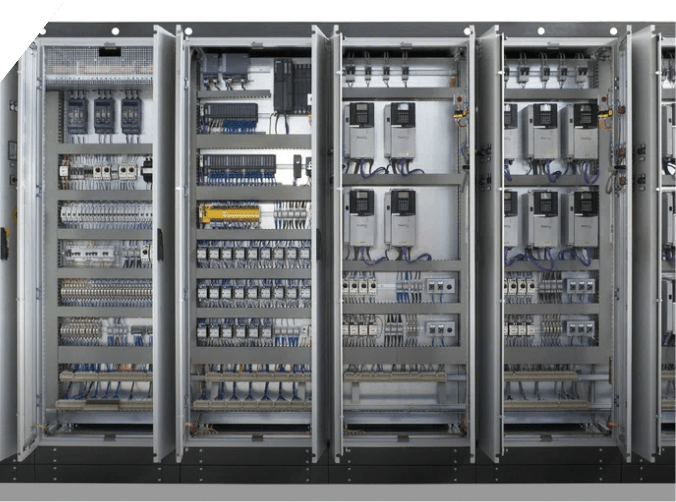

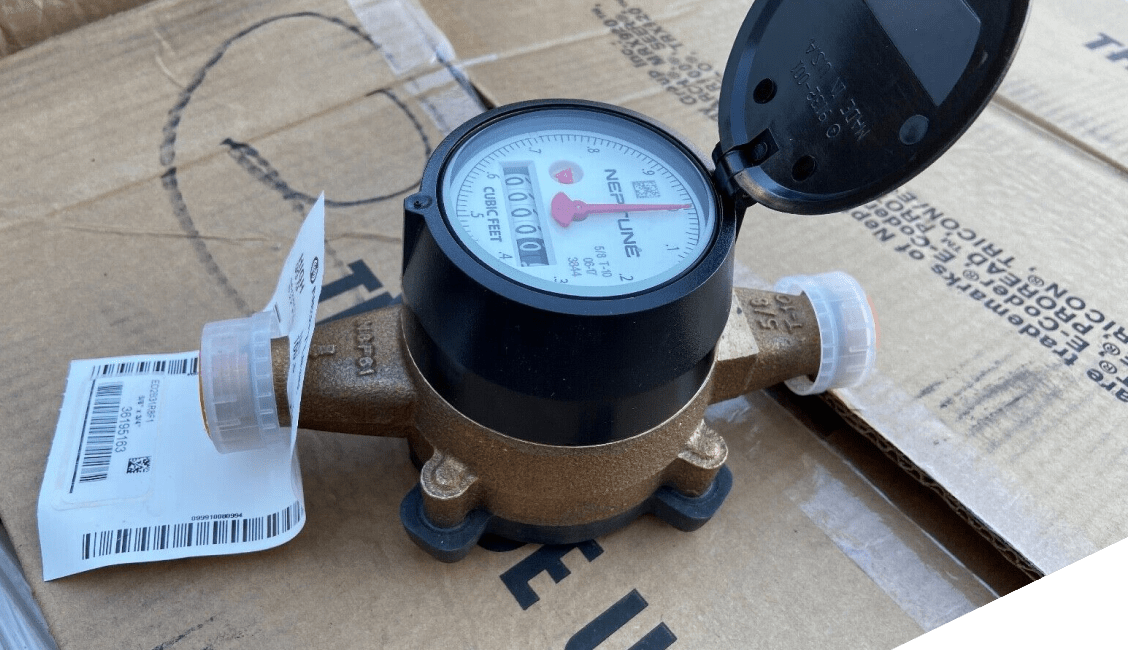

NTEP certified with load cells, butterfly discharge valve, aeration system, and air vibrator, all factory-installed.

Rotary-type indicators to monitor high and low material levels in the silo.

Bar grate decking with handrails, toe boards, and a step-off deck from the safety ladder, ensuring safety during silo maintenance.

Low-pressure regenerative blower system for silo aeration, with optional manifolds for multiple compartments.

All equipment is treated with a zinc primer and polyester polyurethane paint for weather resistance and durability.

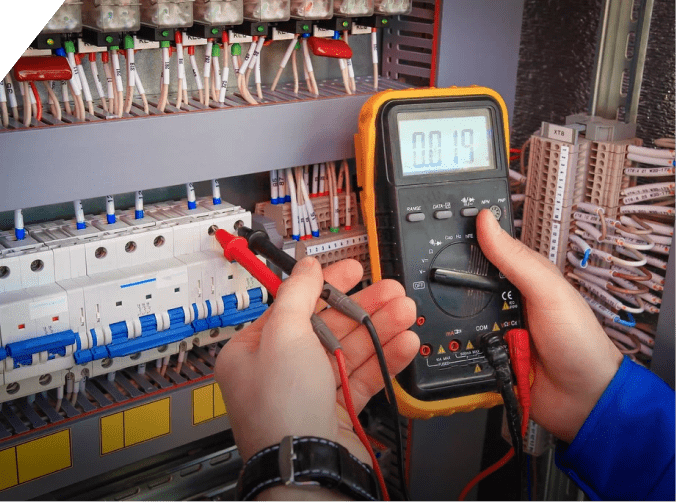

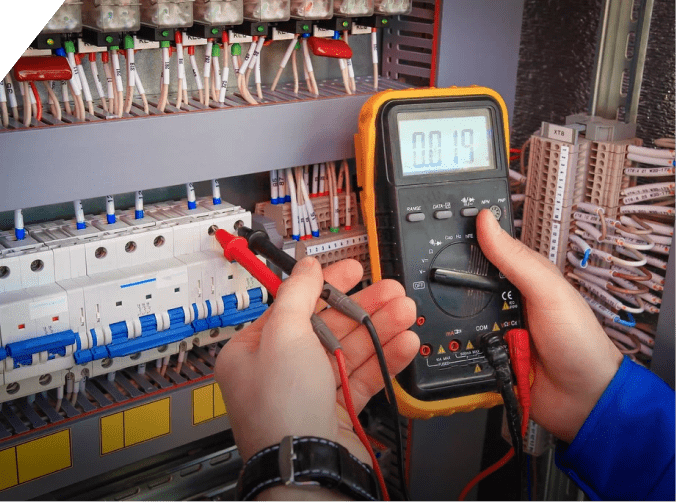

Factory-installed wiring in conduit for reliable electrical connections.

Pre-installed wiring and a NEMA 4 power panel, ready for connection to customer-supplied power.

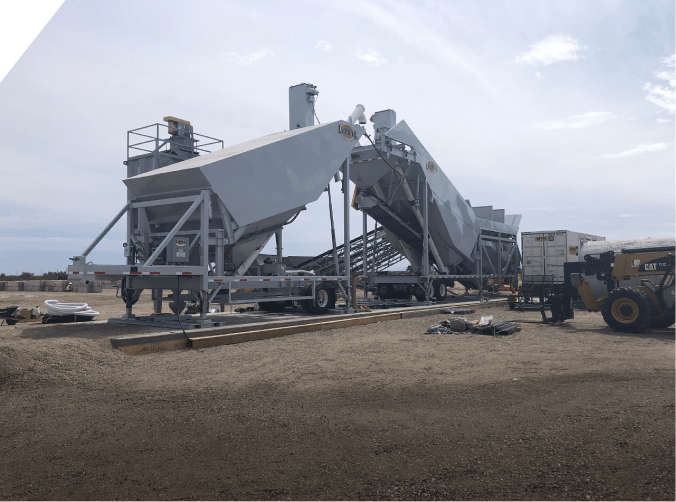

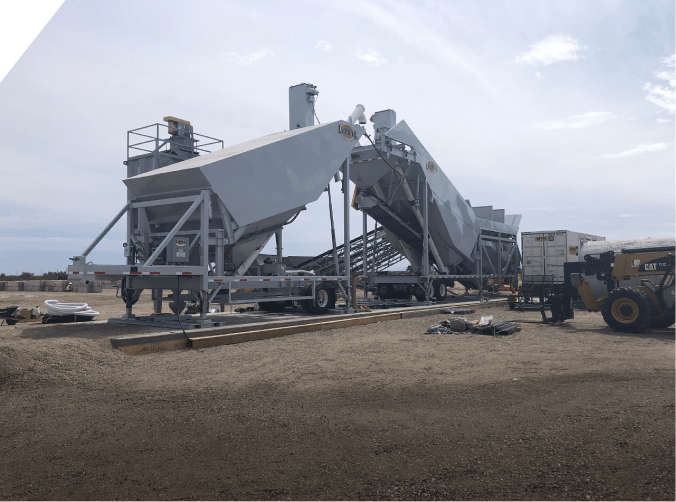

With R&S, you are investing in more than just silo storage; you are equipping your plant with a complete, high-performance cement batching system that maximizes operational efficiency, safety, and longevity. Our batchers and silo systems are designed to optimize your workflow, reduce downtime, and deliver superior results.

Our experienced team is dedicated to providing customized solutions to meet your unique needs. Whether you’re looking to upgrade your silo system or enhance your batching accuracy, we’re here to collaborate with you and ensure your plant operates at its best.

The Auxiliary Arrowhead Silo series offers a range of silos with capacities from 493 BBL to 1160 BBL, designed for efficient storage of bulk materials like cement. Built with heavy-duty welded tubular steel, these silos feature a square roof for added square footage, an externally mounted aeration system, and easy access for inspection with a 20” manhole. Key safety features include a caged ladder, handrails, and toe boards. Additional options like fill line upgrades, anti-overfill systems, aeration blowers, and material handling systems are available for customization. This modular design ensures flexibility and durability for various bulk storage applications.

Capacity: 493 BBL (1972 cubic feet, 73 tons)

Capacity: 600 BBL (2400 cubic feet, 88.8 tons)

Capacity: 720 BBL (2880 cubic feet, 106.6 tons)

Capacity: 943 BBL (3772 cubic feet, 139.6 tons)

Capacity: 1012 BBL (4050 cubic feet, 149.9 tons)

Capacity: 1160 BBL (4640 cubic feet, 171.7 tons)

Safety deck with bar grating, handrails, toe boards, and step-off deck for batcher area.

Adds air reserve for pinch valve operation in after-hours situations.

The Auxiliary Arrowhead Silo series is an ideal storage solution for the concrete industry, offering customizable and reliable options to meet the unique needs of concrete production and storage. These silos are built to withstand the demanding environment of concrete mixing and batching, with robust construction that ensures long-term durability and consistent performance.

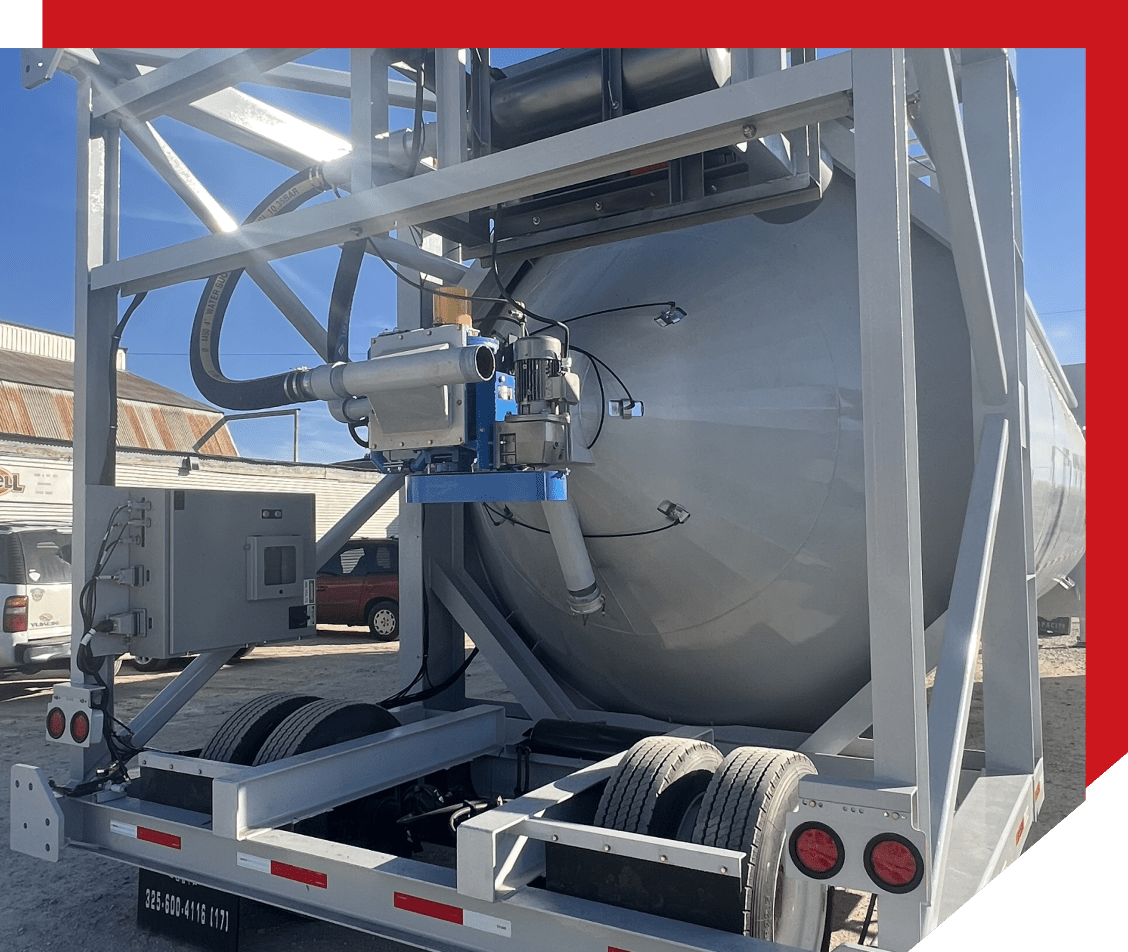

Our Vertical Pig Silos are the ideal solution for concrete plants looking to expand storage capacity without taking up additional floor space. By utilizing vertical space, these silos allow for significant storage increases while maintaining a compact footprint. Designed to fill and discharge simultaneously, the R&S Vertical Pig seamlessly integrates into existing systems, optimizing storage efficiency. Perfect for plants with limited space or those aiming to improve their layout, these silos provide a highly effective way to boost capacity and streamline operations.

Capacity: 720 BBL (2880 cubic feet, 106.6 tons)

Capacity: 943 BBL (3772 cubic feet, 139.6 tons)

Capacity: 1012 BBL (4050 cubic feet, 149.9 tons)

Capacity: 1160 BBL (4640 cubic feet, 171.7 tons)

Heavy-duty welded tubular steel for durability.

Square design increases available space by 22%.

Safety handrails, toe boards, and safety ladder with climbers device. Additional features include:

50-degree cone for material flow, complete aeration system, and clean-out port.

Additional features include a pressure relief valve and an emergency slide gate for material control.

Weather-tight NEMA enclosure for solenoids, with plumbed exhaust lines.

Full-sized air pads, solenoids, and plumbing components.

Provided by the customer, includes a ¾” oversized filter, regulator, and lubricator.

Zinc primer and polyester polyurethane paint for rust protection and durability.

Features: Single axle with four 255/70R22.5 tires, air brakes, and lights.

Purpose: Prevents overfilling by integrating with the high-level bin indicator. Includes a control panel alarm, red strobe light, horn, and a pinch valve that automatically closes when warnings are missed. 43 BBL (3772 cubic feet, 139.6 tons)

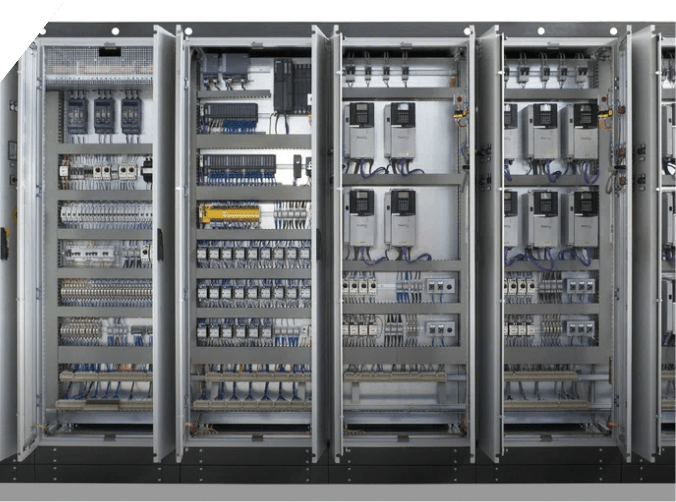

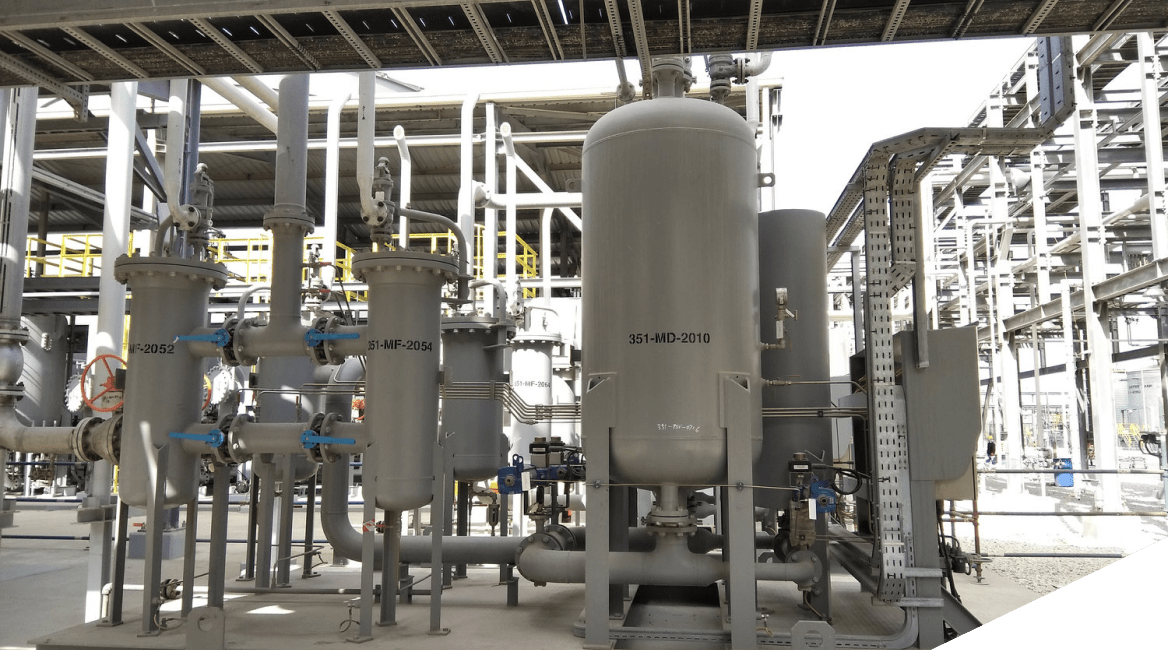

Features: 15 PSI pressure rating, 465 CFM air flow, 4” check valve, and includes a heavy-duty air lock feeder (FT-14). It is designed for high material flow (20–28 tons per hour) and comes with a complete PLC control system for automatic operation based on silo level indicators.

Features: 15 PSI pressure rating, 690 CFM air flow, 5” check valve, and an FT-16 air lock feeder. Designed for higher flow (24–50 tons per hour), it includes the necessary components for smooth, continuous material transfer.

Specifications: Pulse jet collector rated at 2,400 CFM with 99.99% efficiency. Includes (twelve) 8” x 39” cartridges for filtration, 90–100 PSI air requirement, and solid-state reverse pulse cleaning system. Ideal for managing dust during material handling.

“With its robust construction, advanced aeration system, and easy integration into existing operations, the Arrowhead Vertical Pig Silo is the ideal choice for enhancing plant efficiency and meeting the demands of modern concrete production.”