R&S mobile concrete batching plants are an excellent choice for construction projects requiring both flexibility and mobility. Their design ensures easy transportation from one site to another, making them particularly beneficial for temporary or short-term construction projects. These plants are engineered for quick setup, which significantly reduces downtime and the amount of preparation needed before production begins.

In summary, mobile batching plants from R&S provide a highly efficient and convenient solution for construction projects with time-sensitive demands or constantly changing requirements, helping to streamline operations and deliver results promptly.

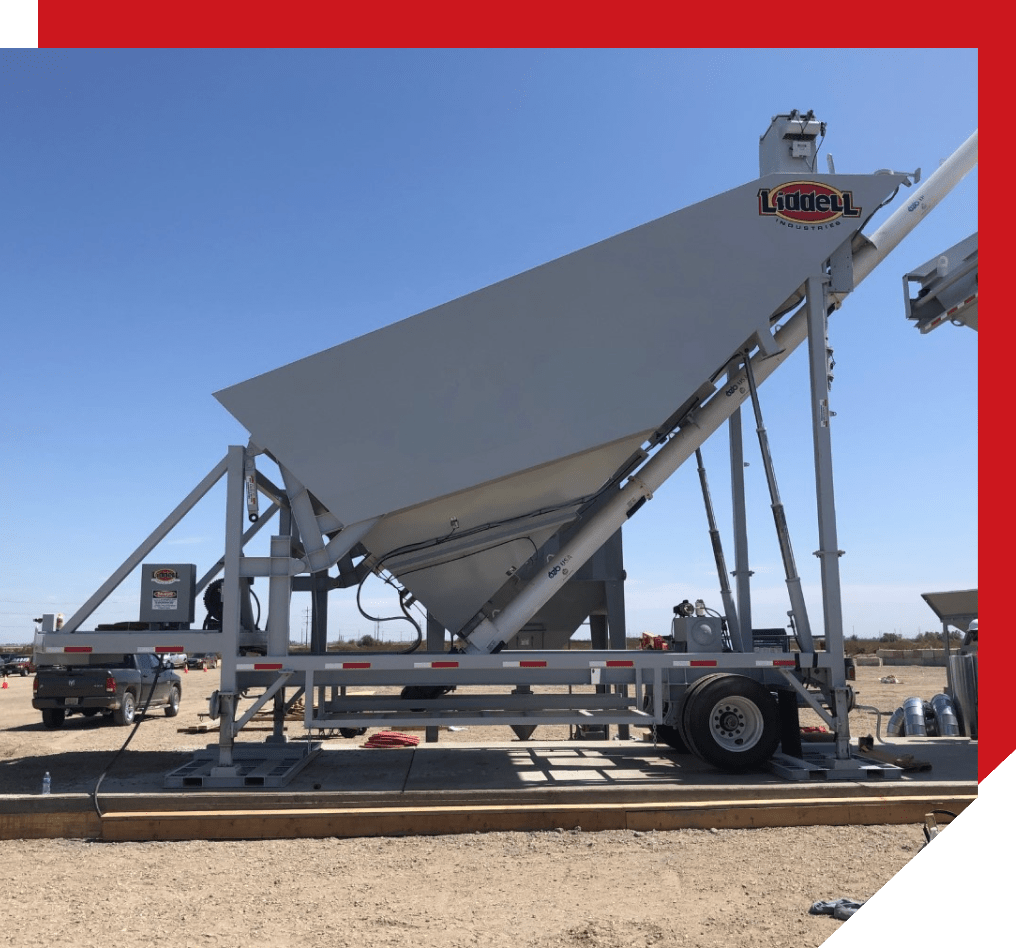

When mobility is a priority, the Dakota 12 is the perfect solution. This self-erecting plant features a hydraulic system that enables quick and easy setup, so you can have it operational in just a few hours without the need for cranes or specialized foundations.

The Dakota 12 offers flexible aggregate storage with capacities ranging from 28 to 36 tons, available in 2 to 4-compartment configurations. Additional bin extensions can be added for increased storage capacity, giving you even more flexibility.

For cement storage, the plant comes standard with a 59.0 Tons / 400 BBL silo, with the option to add a mobile auxiliary silo for an extra 64.0 Tons / 428 BBL. With a theoretical production rate of 160 cubic yards per hour, the Dakota 12 provides excellent efficiency and performance for both large and small-scale production needs.

Whether you’re working on a short-term project or require a plant that can handle heavy-duty, long-term operations, the Dakota 12 is built to deliver high performance wherever you need it.

160 YD³ per hour

No cranes or foundations needed

28–36 tons, with 2–4 compartments

30” wide, capable of running up to 350 FPM

10–15 HP

Includes pressure regulator, lubricators, and moisture trap for consistent air pressure and smooth operation.

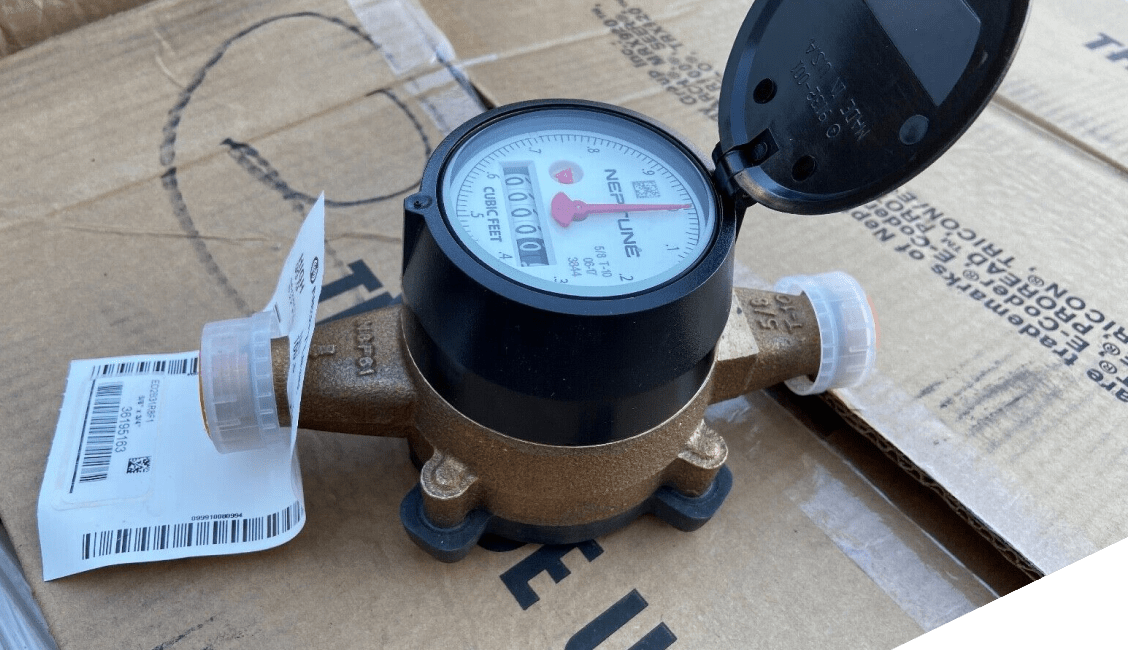

3” turbine type with electronic scalable transmitter and pulse head

3” with replaceable screen

Discharge Valve: 3″ “Bray” butterfly valve with pneumatic actuator and solenoid

4” pneumatic fill line with cam lock fitting and cap, 10” transfer screw conveyors with 25 HP TEFC drive systems for cement transfer, and Emergency slide gates for silo screw conveyor.

Complete aeration system with full-size air pads, solenoid, and required plumbing (easily replaceable from the outside).

8” “Bray” butterfly valve with pneumatic actuator and solenoid. Proximity switch confirms gate closure.

NTEP certified, 4 x 5K, 10,000 lbs scale capacity. Test weight hangers installed at the factory.

Silo Top Dust Collector is a pulse-jet system with a 1,700 CFM capacity and 99.99% cleaning efficiency. It uses six 8” x 54” top-entry cartridges, providing 305 square feet of filtration. It requires 90–100 PSI of clean, dry air.

Batcher Dust Collector is also a pulse-jet system, with a 210 CFM capacity and 99.99% cleaning efficiency. It uses two 5.5” x 20” top-entry cartridges, offering 36 square feet of filtration. Like the silo collector, it requires 90–100 PSI of clean, dry air.

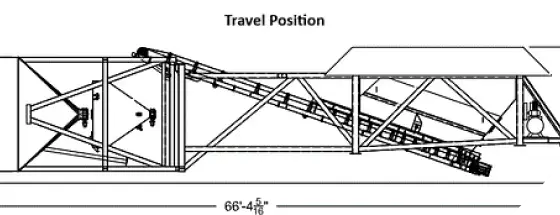

The Dakota 12 is designed for easy transport and can be hauled as a single load. It features a double axle with a suspension system for smooth handling and stability. The system includes eight wheels and tires, air brakes, a king pin, a fifth wheel rub plate, and travel lights, ensuring safe and efficient movement to any job site.

Factory-installed wiring for solenoid valves to a NEMA 12 enclosure on the fifth wheel access platform.

Includes fuses, motor starters, and thermal overload protection for each motor.

No cranes needed, sets up quickly

Available in 2–4 compartments

Includes optional mobile auxiliary silo

No cranes needed, sets up quickly

Erect and operational in just a few hours

Folds down for transport

No cranes needed, sets up quickly

Erect and operational in just a few hours

Folds down for transport

The Dakota 12 is the most mobile plant in the R&S lineup, setting the industry standard for efficiency and cost-effectiveness. Designed for maximum portability, all components of the plant travel as a single load, significantly reducing both setup time and transport costs. Featuring a quick self-erecting hydraulic system, durable construction, and flexible configuration options, the Dakota 12 is a powerful and reliable solution for producers who require mobility, efficiency, and long-term performance. When you want mobility, you want the Dakota 12.

The Apache SQP mobile batching plant is a powerhouse designed for high production outputs, comparable to stationary plants, but with the added benefit of mobility. It can also be configured with a variety of options and upgrades to suit specific project needs. This high-capacity, easy-to-transport mobile plant ensures rapid setup and large-scale production, making it ideal for construction sites that require fast and reliable batching solutions.

120–200 YD³ Per Hour

Provides high-output capacity to meet the needs of demanding projects.

Movable with a single truck for quick transport and setup at job sites.

1541 cubic feet/57 tons/385 max barrels. Fold-down design for travel with a complete aeration system and pressure relief valve. Optional mobile sile for an additional 57 tons of storage.

Externally removable aeration pads provide optimum cement flow and easy maintenance.

Can be equipped with a Pulse-Jet Silo Top or Free-Standing Dust Collection System with an Auto-Dust Reclaim System to reduce environmental impact and improve efficiency.

NTEP certified with an 8” butterfly discharge valve, load cells, and an air vibrator for accurate batching.

Single axle with four 255/70R 22.5 wheels for easy mobility.

Air brakes and travel lights included for compliance and safety during transport.

15 HP/120-gallon air compressor with oversized filters and regulators.

Factory-installed air hoses, solenoids, and quick isolation for easier maintenance.

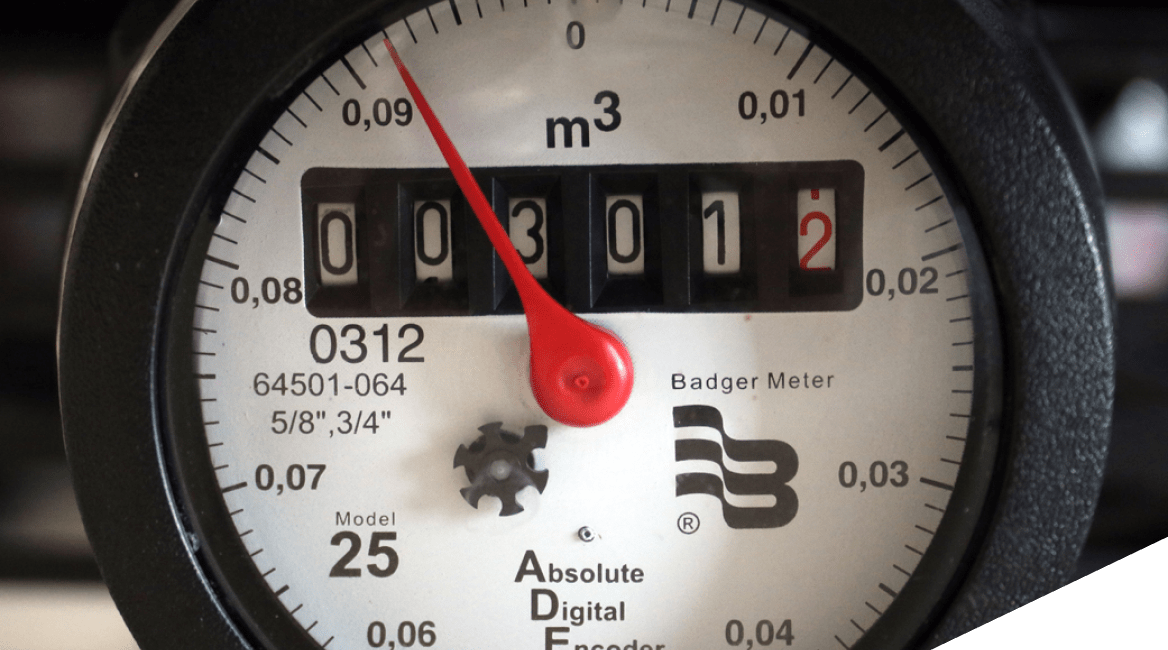

Badger 2” or 3” Turbo Water Meter with standpipe and inlet strainer.

Weighed Water System 500-gallon surge tank constructed of 3/16” plate with 3” inlet system complete with butterfly valve, actuator, and solenoid with air mufflers for a more controlled close rate for precise water measurement.

Badger 3” MAG Water Meter with standpipe and inlet strainer.

Supplies water to both aggregate conveyor and discharge head for efficient batching.

Badger 2” or 3” Turbo Water Meter with standpipe and inlet strainer.

Badger 3” MAG Water Meter with standpipe and inlet strainer.

Weighed Water System 500-gallon surge tank constructed of 3/16” plate with 3” inlet system complete with butterfly valve, actuator, and solenoid with air mufflers for a more controlled close rate for precise water measurement.

Supplies water to both aggregate conveyor and discharge head for efficient batching.

Zinc primer and polyester polyurethane paint for enhanced weather resistance and durability in tough conditions.

The Apache SQP offers a range of options to increase efficiency, enhance control, and expand capacity for different project requirements.

Increases storage capacity up to 160 tons with 3 and 4 compartment extensions.

Provides precise control over material flow.

Simplifies maintenance with an integrated lubrication solution.

Adds more precise control over water batching.

Adds 57 tons of cement storage for larger operations.

Available for the silo top or batcher to maintain a cleaner work environment.

For enhanced mobility and stability.

Provides safe access to the cement batcher.

Prevents overfilling, ensuring smooth operation.

An upgrade to handle larger-scale material charging.

Designed to improve material transfer efficiency.

The Apache SQP 12-Yard – Standard Mobile is designed for maximum flexibility, providing high production rates, easy transport, and numerous customization options. Whether you’re working on a large construction project or a custom batching application, this plant is built to meet your specific needs.