R&S dust collection systems are designed for high-efficiency dust removal in concrete batch plants, providing a cleaner, safer work environment. R&S offers central and silo top dust collectors in various sizes to meet your plant’s specific needs. With 99.9% cleaning efficiency, advanced filtration technology, and durable construction, our systems are designed to tackle concrete production’s unique dust control challenges.

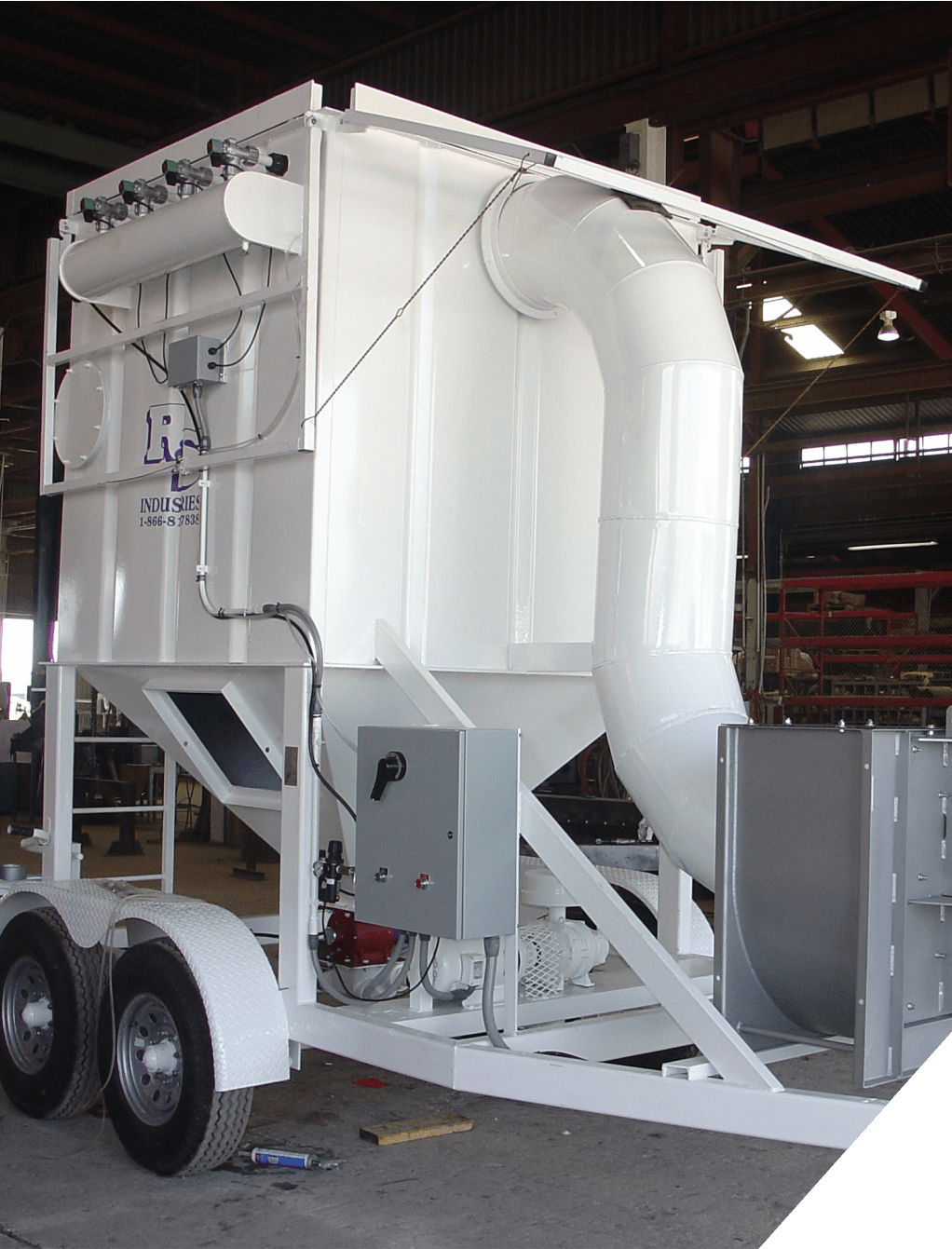

The PJB-1100 Pulse Jet/Bag Dust Collector is designed for high-efficiency dust removal in industrial settings, featuring advanced filtration and a durable construction. Here are the key specifications:

15 HP TEFC motor with sheaves, belts, and a safety guard.

Safety ladder, handrails, and toe boards on both the housing top and blower unit.

Heavy-duty tubular steel construction.

10-gauge steel with two dust inlets.

Includes inspection door and air vibrator for optimal dust handling.

8” Bray butterfly discharge valve with actuator and solenoid.

One compartment with a hinged top for easy filter access.

NEMA 4 enclosure with motor starters and disconnect.

Adjustable solid-state control for air pulse cycle and duration.

Self-contained unit, with electrical supply provided by the customer.

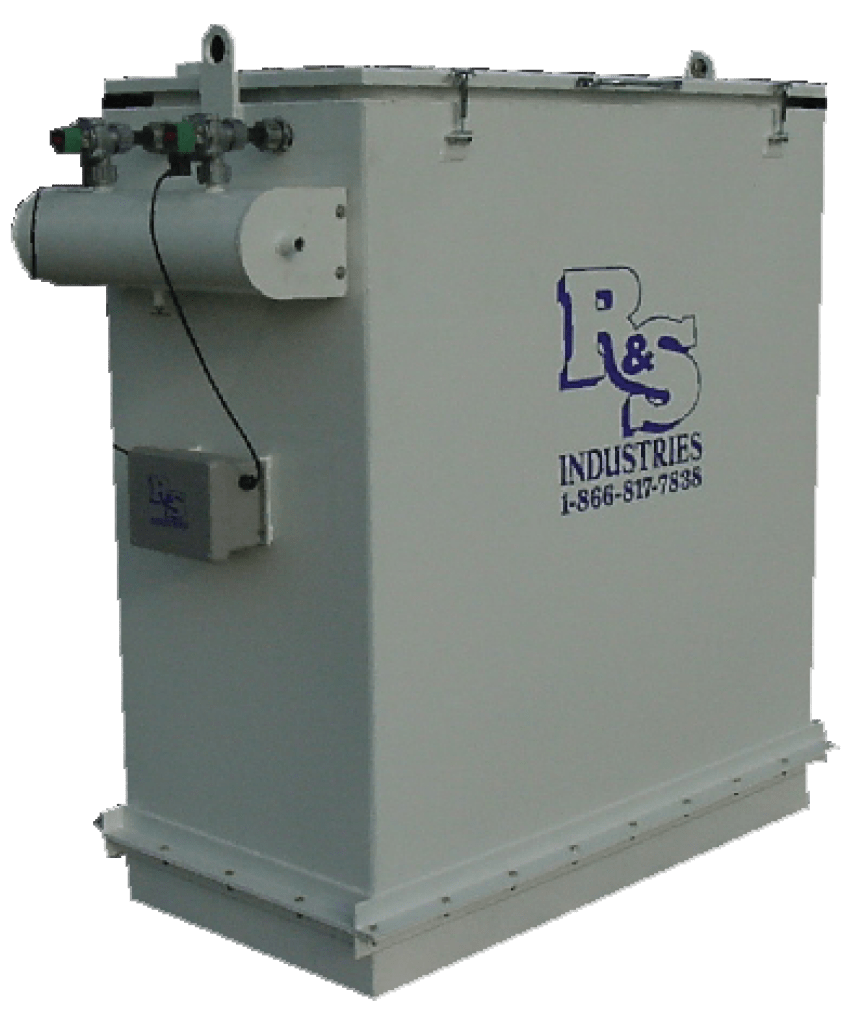

Both the PJC-305 and PJC-425 are pulse jet type silo top dust collectors designed for efficient filtration and dust removal in silo applications. Below are the specifications for each model:

Rated at 2,400 CFM with 99.99% cleaning efficiency.

Rated at 2,400 CFM with 99.99% cleaning efficiency.

Rated at 2,400 CFM with 99.99% cleaning efficiency.

Hinged top entry for convenient system maintenance.

Adjustable control panel for setting pulse duration and cycle times.

Fully pre-wired and tested at the factory before shipment.

Requires 90 – 100 PSI of clean, dry air.

Factory-installed if purchased with a silo. Separate flange available for customer installation.

Zinc primer treatment and polyester polyurethane paint for durability.

Factory-installed if purchased with a silo. Separate flange available for customer installation.

Both models come pre-wired and tested before shipment for ease of installation and reliability.

Both units are treated with a zinc primer and finished with polyester polyurethane paint for long-lasting protection.

Both models require clean, dry air at 90–100 PSI to operate efficiently.

These dust collectors are ideal for silo operations and are designed for easy maintenance, durability, and high-efficiency filtration.